Search This Supplers Products:Steel Pipe ManufacturerWelded Steel Pipe ManufacturerSeamless Steel Pipe ManufacturerERW Steel Pipes Manufacturer

The Difference Between Hot Rolled Steel Plate and Cold Rolled Steel Plate

time2023/06/20

- There are two common manufacturing processes for steel plates: hot rolling and cold rolling. Below we delve into the details of both processes, highlighting their differences and common uses.

When it comes to steel plates, there are two common manufacturing processes: hot rolling and cold rolling. Each process has its distinct characteristics and produces steel plates with different properties. Knowing the difference between hot-rolled and cold-rolled steel is essential for a variety of industries and applications. In this article, we'll delve into the details of both processes, highlighting their differences, advantages, and common uses.

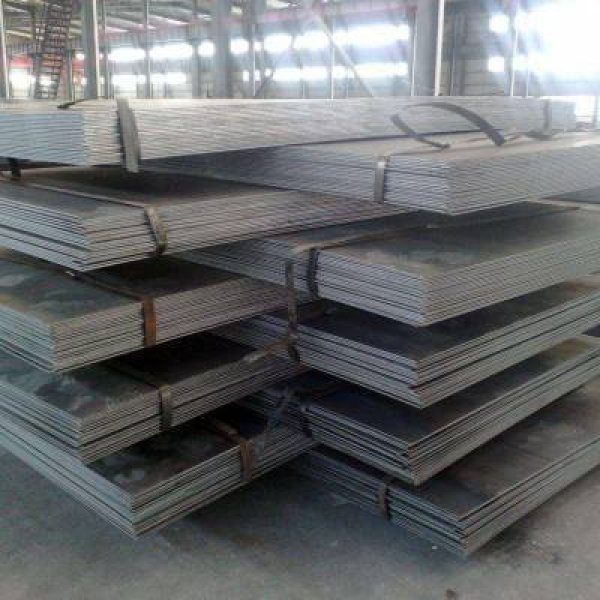

Hot Rolled Steel Plate

Hot-rolled steel plate refers to a type of steel plate formed by a hot-rolling process. In this method, steel is heated above its recrystallization temperature and passed through a series of rollers to achieve the desired thickness and shape.

Manufacturing Process

The manufacturing process of hot rolled steel plate includes the following steps:

Heating: Steel plates are heated to high temperatures, usually above 1,000 degrees Celsius, to make them malleable.

Rolling: A heated slab is passed through a series of rolls that apply pressure to shape the steel and reduce its thickness.

Cooling: After the rolling process, the steel plate is rapidly cooled to room temperature.

Characteristic

Hot-rolled steel sheets have several key properties, including:

Strength: Hot-rolled steel is known for its exceptional strength and durability.

Ductility: The hot rolling process increases the ductility of the steel, making it easier to form.

Toughness: These sheets exhibit good toughness making them suitable for demanding applications.

Advantage

Hot-rolled steel sheets offer several advantages, such as:

Cost-effective: The hot rolling process is relatively efficient and cost-effective compared to other steel plate production methods.

Rapid Production: The high speed of hot rolling enables large-scale production of steel plates in a short period of time.

Improved Mechanical Properties: The hot rolling process improves the mechanical properties of the steel, including its strength and toughness.

Common Use

Hot-rolled steel sheets are used in various industries, including:

Construction: They are widely used in the construction of buildings, bridges, and infrastructure.

Automotive: Hot-rolled steel sheets are used to make automotive frames and structural components.

Shipbuilding: These plates are used to build ship hulls and other marine structures.

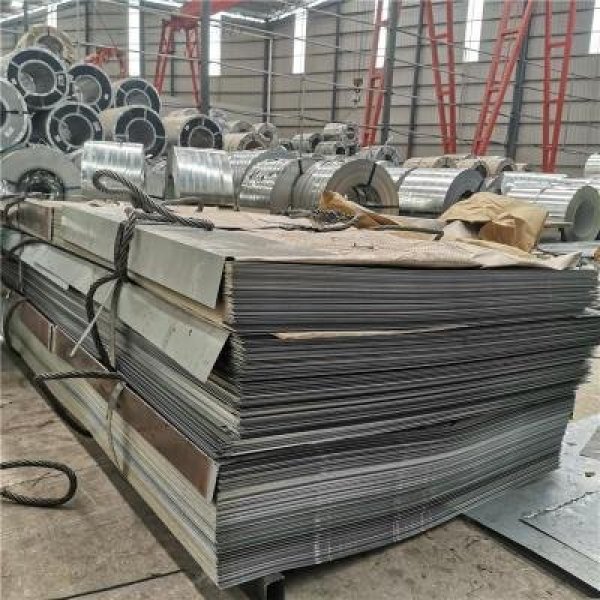

Cold Rolled Steel Plate

Cold rolled steel plate refers to a kind of steel plate produced by the cold rolling process. Unlike hot rolling, cold rolling involves the deformation of steel at room temperature.

Characteristic

Cold-rolled steel sheets have the following properties:

Precise Dimensional Tolerances: Cold rolling ensures excellent dimensional accuracy and tight thickness tolerances.

Improved Surface Finish: The cold rolling process produces a smooth polished surface free of scale and blemishes.

High Strength: Due to the strain hardening effect during cold rolling, cold-rolled steel sheets have higher strength compared to hot-rolled sheets.

Advantage

Cold-rolled steel offers several advantages, including:

Superior Surface Quality: The cold rolling process eliminates surface imperfections, making the sheet suitable for applications requiring a pristine finish.

Excellent Dimensional Accuracy: Cold-rolled sheet has precise thickness and width tolerances, making it ideal for applications where dimensions are critical.

Increased Strength: Cold rolling increases the strength of the steel, making it suitable for applications requiring high tensile strength.

Common Use

Cold-rolled steel sheets are used in a wide variety of industries and applications, including:

Automotive Manufacturing: For the production of automotive body panels, chassis components, and structural parts.

Appliances: Cold-rolled steel sheets are used to manufacture appliances such as refrigerators, washing machines, and ovens.

Metal Furniture: These panels are used to produce metal furniture, including tables, chairs, and cabinets.

Comparison of Hot-Rolled and Cold-Rolled Steel Sheets

Hot-rolled steel plates and cold-rolled steel plates are two completely different steel products with completely different characteristics. Understanding the differences between these two types of steel plates is critical to choosing the right material for a particular application. Let us delve into the detailed comparison between hot-rolled and cold-rolled steel sheets.

Mechanical Behavior:

One of the main differences between hot-rolled and cold-rolled steel sheets is their mechanical properties. Hot-rolled steel sheets tend to exhibit higher overall strength because the hot-rolling process increases the toughness and ductility of the steel. On the other hand, cold rolled sheet has excellent dimensional accuracy and higher tensile strength.

Surface Treatment:

The surface finish of steel plates also varies greatly. The surface of the hot-rolled sheet has a characteristic scale, which is a by-product of the rolling process. In contrast, a cold-rolled sheet has a smooth and polished surface without scale and blemishes. This excellent surface finish makes cold-rolled sheet ideal for applications requiring a pristine appearance.

Dimensional Accuracy:

In terms of dimensional accuracy, cold-rolled steel sheets are superior. The cold rolling process ensures precise thickness and width tolerances, resulting in excellent dimensional accuracy of the plate. In contrast, the hot-rolled sheet may have slightly greater dimensional variation due to the nature of the hot-rolling process.

Cost Considerations:

Cost is another aspect to consider when comparing hot-rolled versus cold-rolled steel. The hot-rolled plate is generally more cost-effective because the hot-rolling process is faster and requires less energy, reducing production costs. However, cold-rolled sheet offers advantages in terms of surface finish and dimensional accuracy, which may prove more costly for some applications.

To sum up, there are obvious differences between hot-rolled steel sheets and cold-rolled steel sheets in terms of manufacturing process, performance, and application. The hot-rolled sheet offers excellent strength, cost-effectiveness, and rapid production, making it suitable for a variety of construction and automotive applications. Cold rolled sheet, on the other hand, excels in surface finish, dimensional accuracy, and high tensile strength, making it ideal for applications requiring precise specifications and excellent surface quality.

The above introduces the difference between cold-rolled steel plates and hot-rolled steel plates. If you want to buy hot-rolled or cold-rolled steel plates, please contact us.

Founded in 1991, Baolai is a comprehensive enterprise integrating industry, trade, and commerce. As a top custom steel plate and steel pipe manufacturer, we are specialized in the production, trade, and import and export of steel plates, steel coils, fire pipes, ERW pipes, HDG steel pipes, seamless steel pipes, LSAW steel pipes, SSAW steel pipes, and building materials. We have more than 20,000 tons of pipe products in stock.

The main industries that consume cold-rolled steel sheets include construction, machine building, automotive.

Hot Rolled Carbon Steel Plate is a flat plate of hot-rolled low carbon steel.