-

-

-

API 5L-0552

Certificate No : 5L-0552

Issuing authority : The American Petroleum Institute

Valid period : 2020/5/25 - 2024/6/15

Scope

1. PURPOSE AND COVERAGEThe purpose of this specification is to provide standards for pipe suitable for use in conveying gas, water, and oil in both the oil and natural gas industries.This specification covers seamless and welded steel line pipe. It includes plain-end, threaded-end, and belled-end pipe, as well as through-the-ftowline (TFL) pipe and pipe with ends prepared for use with special couplings.Although the plain-end line pipe meeting this specification is primarily intended for field makeup by circumferential welding, the manufacturer will not assume responsibility for field welding.2. PRODUCT SPECIFICATION LEVEL (PSL)This specification establishes requirements for two product specification levels (PSL I and PSL 2). These two PSL designations define different levels of standard technical requirements. PSL 2 has mandatory requirements for carbon equivalent, notch toughness, maximum yield strength, and maximum tensile strength. These and other differences are summarized in Appendix 1.Requirements that apply to only PSL I or only PSL 2 are so designated. Requirements that are not designated to a specific PSL apply to both PSL I and PSL 2.The purchaser may add requirements to purchase orders for either PSL I or PSL 2, as provided by the supplementary requirements (Appendix F) and other options (4.2 and 4.3).3. GRADESThe grades (see the note) covered by this specification are the standard Grades A25, A, B, X42, X46, X52, X56, X60, X65, X70 and X80; and any intermediate grades (grades that are higher than X42, intermediate to two sequential standard grades, and agreed upon by the purchaser and manufacturer).PSL I pipe can be supplied in Grades A25 through X70.PSL 2 pipe can be supplied in Grades B through X80.Class II (CI II) steel is rephosphorized and probably has better threading properties than Class I (CI l). Because Class II (CI II) has higher phosphorus content than Class I (CI l), it may be somewhat more difficult to bend.Pipe manufactured as Grade X60 or higher shall not be substituted for pipe ordered as Grade X52 or lower without purchaser approval.Note: The grade designations are dimensionless. Grades A and B do not include reference to the specified minimum yield strength; however, other grade designations are composed of the letter A or X, followed by the first two digits of the specified minimum yield strength in U.S. Customary units.4. DIMENSIONSThe sizes used herein are dimensionless designations, which are derived from the specified outside diameter as measured in U.S. Customary units, and provide aconvenient method of referencing pipe size within the text and tables (butnot for order descriptions). Pipe sizes 23/8 and larger are expressed as integers and fractions; pipe sizes smaller than 23/8 are expressed to three decimal places. These sizes replace the "size designation" and the "nominal size designation" used in the previous edition of this specification. Users of this specification who are accustomed to specifying nominal sizes rather than 00 sizes are advised to familiarize themselves with these new size designations used in this specification, especially the usage in Tables 4, 5, and 6A.PSL I pipe can be supplied in sizes ranging from 0.405 through 80.PSL 2 pipe can be supplied in sizes ranging from 4'/2 through 80.Dimensional requirements on threads and thread gages, stipulations on gaging practice, gage specifications and certification, as well as instruments and methods for inspection of threads are given in API Standard 5B and are applicable to threaded products covered by this specification.

-

-

-

-

API 5CT -0755

Certificate No : 5CT-0755

Issuing authority : American Petroleum Institute

Valid period : 2021/6/15 - 2024/6/15

ScopeThis Standard specifies the technical delivery conditions for steel pipes (casing, tubing and pup joints), coupling stock, coupling material and accessory material and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3).The requirements for PSL-1 are the basis of this Standard.The requirements that define different levels of standard technical requirements for PSL-2 and PSL-3, for all Grades except H-40, L-80 9Cr and C110, are contained in Annex H.Peotroleum and natureal gas industies – Steel pipes for use as casing or tubing for wells.Standard: API SPEC 5CTAPI 5CT pipe Size (mm):· Outer Dimensions: 6.0mm – 219.0mm· Wall Thickness: 1.0mm – 30 mm· Length: max 12000mmApplication: gas, water and oil transportation in both oil and natural gas .The main steel grade of API 5CT:· API 5CT J55, API 5CT K55, API 5CT N80, API 5CT L80, API 5CT P110.Packing: Bare/bundles/crates/crate protection at the both sides of tubes or as per customers’ requirements .This International Standard is applicable to the following connections in accordance with ISO 10422 or API Spec 5B:· short round thread casing (STC);· long round thread casing (LC);· buttress thread casing (BC);· extreme-line casing (XC);· non-upset tubing (NU);· external upset tubing (EU);· integral joint tubing (IJ).For such connections, this International Standard specifies the technical delivery conditions for couplings and thread protection.For pipes covered by this International Standard, the sizes, masses, wall thicknesses, grades and applicable end finishes are defined.This International Standard may also be applied to tubulars with connections not covered by ISO/API standards.

-

-

-

-

JIS G3444

Certificate No : KSCNA15007

Issuing authority : Korea Certificate Association

Valid period : 2021/12/19 - 2024/12/28

Scope

This Japanese Industrial Standard specifies requirements for the carbon steel tubes (hereafter referred to as tubes), used for civil engineering and architecture such as steel towers, scaffoldings, footing piles, foundation piles, piles for landslide suppression.NOTEThe dimensional range covered by this Standard is generally outside diameter 21.7 mm to 1 016.0 mm. In application for foundation piles and piles for landslide suppression, however, this Standard is mainly applicable to tubes of outside diameter under 318.5 mm, and JIS A 5525 applies mainly to welded steel tubes of outside diameter 318.5 mm or over.Japanese Industrial Standards (JIS) developed by the organization apply to a wide variety of industrial services and technologies such as automobiles, metallurgy, ships and medical equipment.JIS G3444 STK500 steel tube/pipe, seamless steel tubes/pipes and welded steel tubes/pipesJIS G3444 is the standard of carbon steel tubes for general structural purposes, STK500 steel tubes/pipes used for civil engineering, architecture, steel towers, scaffoldings, struts, piles for suppression of landslide and other structures.

-

-

-

-

JIS G3452

Certificate No : KSCN15008

Issuing authority : Korea Certificate Association

Valid period : 2021/12/29 - 2024/12/28

JIS G34521. ScopeThis Japanese Industrial Standard specifies the carbon steel pipes, hereinafter referred to as the “pipes”, used for the piping for conveying steam, water, oil, gas, air, etc. At comparatively low working pressures.Remark: The units and numerical values given in { } in this Standard are based on the International System of Units (SI) and are appended for informative reference.Further, the traditional units accompanied by numerical values in this Standard shall be converted to the SI units and numerical values on Jan. 1, 1991.2. Grade and DesignationThe pipe shall be classified into one grade and its letter symbol shall be as shown below., and subdivided into black pipes and galvanized ones according to nonexistence of existence of zinc-coated layers.

Letter symbol of grade

Division

Remark

SGP

Black pipe

Pipe without zinc coating

Galvanized pipe

Pipe with zinc coating

Remark: Where it is necessary to identify the galvanized pipe by the letter symbol on the drawing and other documents, “-ZN” shall be suffixed to the letter symbol of the grade. This notation, however, shall not be applied to the product itself.

-

-

-

-

ISO 9001

Certificate No : 19817QH088R1M

Issuing authority : Beijing XInjiyuan Certification Co., Ltd

Valid period : 2020/8/24 - 2023/8/24

ScopeImportant notice: the ISO 9001 Standard requirements apply the final product supplied to the customer and not apply the internal processes and intermediate or middle products. Therefore the scope shall include the final product. Customer may be considered as internal customer as well as external customer. Now, after clearing this, let’s get down to business. Clause 1 of the ISO 9001 Standard is used to present the purposes and concepts of the standard and define the scope of application of the standard to your quality management system. The following aspects are covered in this clause:The goals and purposes of the standardThe approach and reference to customer requirementsThe approach and reference to regulatory or statutory requirementsApplicability of the standard requirementsThe Principles of the ISO 9001:2015 StandardClause 1—Scope presents us with the principles and concepts of the standard. The ISO 9001 Standard is aimed to satisfy customers by fulfilling its requirements along with applicable international and national regulations. This is expressed through four principles:1. The goal and objective of the standard is to initiate a QMS that acts to consistently meet customer requirements as well as applicable regulatory requirements.2. The requirements of this standard initiate harmonization between a QMS of an organization and applicable regulatory requirements.3. The requirements suggested in the ISO 9001 Standard facilitate an improvement of processes included in the QMS and assurance of conformity to customer or regulatory requirements.4. The requirements suggested in the ISO 9001 Standard are applicable to all sorts of organizations regardless of their size or type, the type of their customers, and the type of products or services that they are providing.The international ISO 9001 standard specifies requirements for a quality management system where an organization:Is required to demonstrate is ability to supply persistently and continually product that meets specific requirements (customer’s or regulatory). The standard requirements would ensure that the organization shall achieve requirements it is obliged to.Has defined objectives for achieving customer’s satisfaction. This objective shall be achieved by implementing effectively a quality management system. The quality management system shall include:Continual improvement activities.Assurance of conformity to customer’s requirementsAssurance of conformity to regulatory requirements

-

-

-

-

ISO 14001

Certificate No : 19817EH039R1M

Issuing authority : Beijing XInjiyuan Certification Co., Ltd

Valid period : 2020/8/24 - 2023/8/24

ISO 14001ISO 14001 Clause 1 relates to the scope or coverage of the standard to help organizations achieve the intended outcomes of its' EMS.The standard encourages businesses to implement processes and systems to ensure consistent product and service output, while ensuring that customer satisfaction is enhanced through conformity and improvement.Aims of the ScopeThe scope or goal aims to determine what types of operations your company's Environmental Management System will cover and any boundaries or limitations that might be placed on it.Once these boundaries have been set out, you will have a clear vision and outline of the various departments in your company that will be subjected to the Environmental Management System. These will include;All necessary processesAll participating sitesAll relevant divisionsAll relevant departmentsTo outline the scope of the EMS, clear descriptions of your company's services and products need to be made. This will include descriptions of the products, where and how they are made, and distributed locally or internationally.

-

-

-

-

ISO 45001

Certificate No : 19817SH040R1M

Issuing authority : Beijing XInjiyuan Certification Co., Ltd

Valid period : 2020/8/24 - 2023/8/24

ISO 45001The Final Draft International Standard (FDIS) of ISO 45001, the Occupational Health and Safety Management System standard was published in late November with the final version to be published in February/March 2018. The final standard will be published with only very minor changes to the FDIS version. This is the third in a series of blogs, in which we will describe what the implementing company must do in order to meet the requirement of the draft standard. We will look at clause 4.3: Determining the scope of the OH&S management system.OH&S management systemClause 4.3: Determining the scope of the OH&S management systemClause 4.1 requires the organization to understand the internal and external issues that can impact in a positive or negative manner on its health and safety performance including, inter alia, organizational culture and structure, and the external environment including cultural, social, political, legal, financial, technological, economic, market competition and natural factors of significance to its performance.Clause 4.2 requires the organization to identify relevant interested parties and their needs and expectations.Once the organization has determined and assessed its internal and external issues and identified the needs and expectations of relevant interested parties, including its workforce, it should then define the boundaries and applicability of the OH&S management system. The scope of the OH&SMS can include the whole organization, or specific and identified functions or sections of the organization. Therefore, if the organization makes a statement that it conforms to ISO 45001, then it must make the scope of the management system available so that interested parties clearly understand what parts of the organization are covered.The scope of the management system should include everything under the organization’s control or influence that could impact its OH&S performance. The credibility of the organization’s OH&S management system will largely depend on the extend of the defined boundaries. Under no circumstances should the scope be used to exclude activities, products or services that have or could have the potential to impact the organization’s OH&S performance, or to evade its legal and other requirements.An inappropriately narrow or exclusive scope could undermine the credibility of the organization’s OH&S management system with its interested parties and reduce its ability to achieve the intended outcomes of the occupational health and safety management system.The scope is a factual statement of the organization’s operations or business processes to be included within its OH&S management system boundaries.Once the scope is defined, the concept of ‘organization’ is limited to what the scope covers, e.g. if the scope of the OH&S management system is limited to a particular function or section of the organization, the remainder of the organization is then considered to be an external provider or other interested party.The organization should maintain the scope of OH&S management system as documented information and make it available to interested parties. There are several methods for so doing, e.g. using a written description, inclusion on a site map, an organizational diagram, a webpage, or posting a public statement of its conformity. When documenting its scope, the organization should consider using an approach that identifies the activities or processes involved, the products or services that ensue, and the location(s), where they occur.

-

-

-

-

UL ASTM A53/ ASTM A795

Certificate No : 20170816-EX16094

Issuing authority : UL

Valid period : 2018/8/16 - 2023/8/16

IntroductionUL stands for Underwriter Laboratories, a third-party certification company that’s been around for over a century. UL was founded in 1894 in Chicago. They certify products with the aim to make the world a safer place for both workers and consumers. Besides testing, they set industry standards to follow when innovating new products. Last year alone, about 14 billion products with the UL seal entered the global marketplace.In a nutshell, UL is a safety organization that sets industry-wide standards on new products. They continually check these products to ensure they’re up to these standards. UL testing makes sure that wire sizes are correct or devices can handle the amount of current they claim to be able to. They also ensure that products are constructed correctly for the highest safety.Far more testing is involved in UL Listed certification. The UL Listed seal means that the product has been tested by UL to nationally recognized safety and sustainability standards. Additionally, it has been found to be free from a reasonably foreseeable risk of fire, electric shock in a Division 2 environment. Division 2 environment refers to an area where ignitable concentrations are used.

-

-

-

-

UL ASTM A852

Certificate No : 20170816-EX16094

Issuing authority : UL

Valid period : 2017/8/16 - 2023/8/16

IntroductionUL stands for Underwriter Laboratories, a third-party certification company that’s been around for over a century. UL was founded in 1894 in Chicago. They certify products with the aim to make the world a safer place for both workers and consumers. Besides testing, they set industry standards to follow when innovating new products. Last year alone, about 14 billion products with the UL seal entered the global marketplace.In a nutshell, UL is a safety organization that sets industry-wide standards on new products. They continually check these products to ensure they’re up to these standards. UL testing makes sure that wire sizes are correct or devices can handle the amount of current they claim to be able to. They also ensure that products are constructed correctly for the highest safety.Far more testing is involved in UL Listed certification. The UL Listed seal means that the product has been tested by UL to nationally recognized safety and sustainability standards. Additionally, it has been found to be free from a reasonably foreseeable risk of fire, electric shock in a Division 2 environment. Division 2 environment refers to an area where ignitable concentrations are used.

-

-

-

-

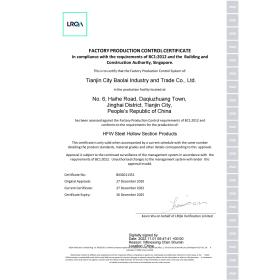

LR 1

Certificate No : BJG6011351

Issuing authority : Lloyd's Register Verification

Valid period : 2010/12/27 - 2025/12/26

A Type Approval from Lloyd’s Register demonstrates that our product conforms to recognised industry quality standards, International Conventions and/or the LR Rules.BAOLAI has been assessed against the Factory Production Control requirements of BC1:2012and conforms to the requirements for the production of: ERW Steel Hollow Section Products.This certificate is only valid when accompanied by a current schedule with the same number detailing the product standards, material grades and other details corresponding to this approval.Approval is subject to the continued surveillance of the management system in accordance with the requirements of BC1:2012. Unauthorised changes to the management system will render this approval invalid.LR Type Approval (against relevant requirements)Under this category, products are type approved against the requirements of an agreed standard or standards. Standards can be national (for example, flag administration requirements from bodies such as the UK MCA and Transport Canada); international (for example, ISO Standards) or any other type of specific requirement (for example, the LR Rules).EU Mutual RecognitionSelected components and equipment, for which technical requirements have been developed and agreed by all European Union (EU) recognised organisations (ROs), can be type approved against this scheme.Approval of Welding Consumables, Non-Metallic Materials and CoatingUnder this category, the manufacturer’s plant, method of production and the product can be approved subject to satisfactory inspection of the works and/or type testing. Typically, products need to comply with the LR Rules and international standards.

-

-

-

-

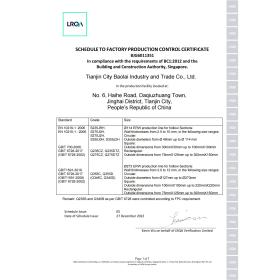

LR 2

Certificate No : BJG6011351

Issuing authority : Lloyd'd Register Verification

Valid period : 2010/12/27 - 2025/12/26

A Type Approval from Lloyd’s Register demonstrates that our product conforms to recognised industry quality standards, International Conventions and/or the LR Rules. It is available for a wide range of products used in marine and offshore applications, industrial plant and processes, and the information technology sector.

Standard

Grade

Size

EN 10219-1:2006EN 10210-1:2006GB/T 700-2006GB/T 6728-2017GB/T1591-2018GB/T 6728-2017

S235JRH,S275JOH,S275J2H,S355JOH,S355J2HS355J0H.S355J2HQ235BZ,Q235CZ,Q235DTZ,Q275BZ,Q275CZ,Q275DTZQ355B,Q355C,Q355D

Ø114 ERW production line for hollow Sections:Wall thicknesses from 2.5 to 10 mm, in the following size ranges:Circular: Outside diameters from Ø48mm up to Ø 114 mmSquare: Outside dimensions from 30mmX30mm up to 100mmX100mmRectangular: Outside dimensions from 75mmX125mm up to 300mmX150mmØ273 ERW production line for hollow Sections:Wall thicknesses from 3.0 to 12 mm, in the following size ranges:Circular: Outside diameters from Ø127mm up to Ø273mmSquare: Outside dimensions from 100mmX100mm up to 220mmX220mmRectangular: Outside dimensions from 75mmX125mm up to 300mmX150mm

-

-

-

-

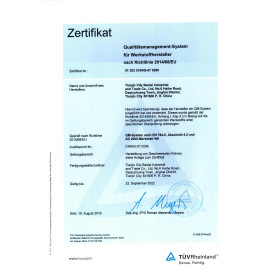

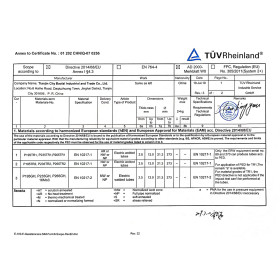

Quality-Assurance

Certificate No : 01202CHN/Q-070256

Issuing authority : TUV

Valid period : 2019/8/19 - 2022/12/23

TÜVHerewith we certify that the material manufacturer has established and applies a Quality Management System The system was audited according to the EuropeanDirective 2014/68/EU,Annex I,Par.4.3,with regard to the materials as listed in the scope of approval.What is TÜV?TÜV is short for Technischer Überwachungsverein in German, which means Technical Inspection Association. These associations are independent companies that test, inspect, and certify technologies, products, and systems to ensure potential hazards and prevent damages.Highly recognized worldwide as a trademark of trust and quality, a TÜV certification ensures that a product, service, or process has been tested for safety and that it complies with the requirements of national, regional, and international regulations. It assures consumers that the product has been checked thoroughly for any defects or potentially dangerous materials.Quality of AssuranceAchieving a TÜV certification means our company’s products have attained the requirements of safety, quality, and sustainability. This gives resellers and partners the confidence to work with us and consumers the peace of mind to use our products.

-

-

-

-

Quality-Management-System

Certificate No : 01202CHN/Q-070256

Issuing authority : TUV

Valid period : 2019/8/19 - 2022/12/23

TÜVHiermit wird bescheinigt, dass der Hersteller ein QM-System eingefuhrt hat und anwendet.Dieses wurde gemaß der Richtlinie 2014/68/EU,AnhangIKap 4.3 in Bezug auf die im Geltungsbereich genannten Werkstoffe einer spezifischen Überprüfung unterzogen.QM-System nach EN 764-5, Abschnitt 4.2 und AD 2000-Merkblatt WoWhat is TÜV?TÜV is short for Technischer Überwachungsverein in German, which means Technical Inspection Association. These associations are independent companies that test, inspect, and certify technologies, products, and systems to ensure potential hazards and prevent damages.Highly recognized worldwide as a trademark of trust and quality, a TÜV certification ensures that a product, service, or process has been tested for safety and that it complies with the requirements of national, regional, and international regulations. It assures consumers that the product has been checked thoroughly for any defects or potentially dangerous materials.Quality of AssuranceAchieving a TÜV certification means our company’s products have attained the requirements of safety, quality, and sustainability. This gives resellers and partners the confidence to work with us and consumers the peace of mind to use our products.

-

-

-

-

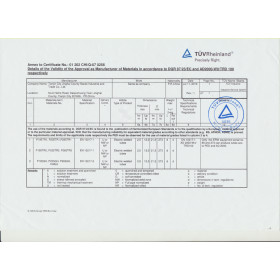

EN 10217 material according to DGRL 97/23/EC

Certificate No : 01202CHN/Q-070256

Issuing authority : TUV

Valid period : 2019/7/10 - 2023/7/11

EN 10217The use of the materials according toDGR 97/23 EC is bound to the publication of Harmonized European Standards or to the qualification by a European matdri seorova or to the particular material appraisal.With that the manufacturing reliability for equivalent material grades according to other standards(e.g.BS,AFNOR,ASM) is proved. The requirements and limits of the applicable code respectively the PED must be observed for the use of material grades listed in column 2 to 4.This part of this European Standard specifies the requirements, under the regime of the EU Directive 97/23/EC on Pressure Equipment (PED), for the establishment of the technical delivery conditions in form of:- harmonised European Standards for material;- European Approval for Materials (EAM);- Particular Material Appraisal (PMA)for metallic materials for pressure equipment in all product forms. Welding consumables are not covered by this standard.NOTE: This standard was developed predominantly on the basis of steel materials. However, application to other materials is not restricted but must consider specific aspects relevant to the material concerned

-

-

-

-

EN 10217 Directive 2014/68/EU

Certificate No : 01202CHN/Q-070256

Issuing authority : TUV

Valid period : 2019/7/10 - 2023/7/11

EN 10217European Standards is an expression of requirements for products, processes or services to meet the requirement of fitness for a particular purpose.This is to certify that the manufacturer applies a quality management system with relation to the welding technology. The manufacturer has demonstrated that the welding requirements for the manufacturing of pressure equipment are fulfilled.Welded steel tubes for pressure purposes - Technical delivery conditions Part 1: Electric welded and submerged arc welded non-alloy steel tubes with specified room temperature properties.The use of the materials according to Directive 2014/68/U is bound to the publication of Harmonized European Standards or to the qualification by a European material approval or to theparticular material appraisal.With that the manufacturing reliability for equivalent material grades according to other standards(e.g.BSAFNOR,ASME)is proved.The requirements and limits of the applicable code respectively the PED must be observed for the use of material grades listed in column 2 to 4.

-

-

-

-

China's top 500 manufacturing industries

Issuing authority : All China Chamber of Commerce

Valid period : 2020/9/1 - 2022/12/31

Baolai Group is a comprehensive enterprise with industry, trade and commerce, which was established in 1991.Tianjin Baolai Fortune is one of the trade companies of Baolai Group.We have been awarded "Top 100 Enterprises of Tianjin" for two consecutive years, titled among the "TOP 500 Enterprises in China Manufacturing Industry" for 5 consecutive years and a credit rating "AAA" by Banks.Tianjin Baolai Industry and Trade Co., Ltd. is ranked 350th among the top 500 private manufacturing enterprises in China.In 2022, Baolai has won the 327th in China's manufacturing industry.Manufacturer StrengthAs the top manufacturer, we specialize in producing, trading, importing and exporting Fire pipes, ERW pipes, HDG steel pipes, Seamless steel pipes, LSAW steel pipes, SSAW steel pipes and building materials.Baolai have about 1300 employees and 13 production lines, many processing lines and 4 laboratories with advanced technology now. Our annual capacity is approximately 5 million tons and exports of 150,000 MT per year to South and North America, Europe, the Middle East, Africa, Australia and Southeast Asia.

-

-

-

-

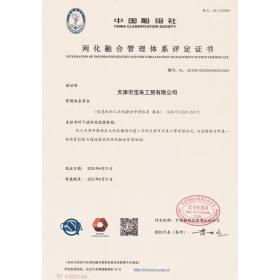

The two integration management system evaluation certificate

Issuing authority : China Classification Society Quality Certification

Valid period : 2020/8/31 - 2023/8/31

Tianjin Baolai Industry and Trade Co., Ltd.management system compliance"Informatization and Industrialization Integration Management System Requirements" (GB/T23001-2017)This certificate is valid for the following assessment scopes:Tianjin Baolai Industry and Trade Co., Ltd. is located at No. 6 Zhenhai River Road, Daqiuzhuang, Jinghai District, Tianjin.Integrated management activities related to integrated management and control capacity building.On August 31, 2020, BAOLAI successfully passed the requirements for “informatization and industrialization integration management system” (GB/T23001-2017) issued by the Ministry of industry and information technology of the people’s Republic of China, and obtained the evaluation certificate of integrated management system of industrialization and industrialization.To passing the certification of the integrated management system of the two technologies signifies that our company has made new breakthroughs in advancing the integration of informatization and industrialization. It provides scientific and effective guidance for the company’s sustainable development, promotes the organic combination of strategic goals and informatization work, creates a comprehensive information system platform, and provides customers with high-quality products and professional services.

-

-

-

-

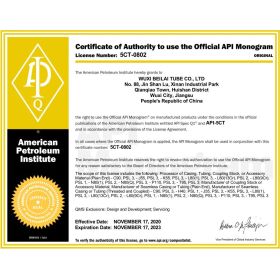

API 5CT -0802

Certificate No : 5CT-0755

Issuing authority : American Petroleum Institute

Valid period : 2023/11/17 - 2024/6/15

ScopeThis Standard specifies the technical delivery conditions for steel pipes (casing, tubing and pup joints), coupling stock, coupling material and accessory material and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3).The requirements for PSL-1 are the basis of this Standard.The requirements that define different levels of standard technical requirements for PSL-2 and PSL-3, for all Grades except H-40, L-80 9Cr and C110, are contained in Annex H.Peotroleum and natureal gas industies – Steel pipes for use as casing or tubing for wells.Standard: API SPEC 5CTAPI 5CT pipe Size (mm):· Outer Dimensions: 6.0mm – 219.0mm· Wall Thickness: 1.0mm – 30 mm· Length: max 12000mmApplication: gas, water and oil transportation in both oil and natural gas .The main steel grade of API 5CT:· API 5CT J55, API 5CT K55, API 5CT N80, API 5CT L80, API 5CT P110.Packing: Bare/bundles/crates/crate protection at the both sides of tubes or as per customers’ requirements .This International Standard is applicable to the following connections in accordance with ISO 10422 or API Spec 5B:· short round thread casing (STC);· long round thread casing (LC);· buttress thread casing (BC);· extreme-line casing (XC);· non-upset tubing (NU);· external upset tubing (EU);· integral joint tubing (IJ).For such connections, this International Standard specifies the technical delivery conditions for couplings and thread protection.For pipes covered by this International Standard, the sizes, masses, wall thicknesses, grades and applicable end finishes are defined.This International Standard may also be applied to tubulars with connections not covered by ISO/API standards.The scope of this license includes the following: Processor of Casing, Tubing, Coupling Stock, or Accessory Material (Plain End)-C90, PSL 3,-J55, PSL 3,- K55, PSL 3, -L80(1), PSL 3,- L80(13Cr), PSL 2.- L80(9Cr).PSL 1,-N80(1),PSL 2,-N80(Q),PSL 3,-P110,PSL 3,-T95,PSL 3;Manufacturer of Coupling Stock or Accessory Material, Manufacturer of Seamless Casing or Tubing (Plain End), Manufacturer of Seamless Casing or Tubing (Threaded and Coupled)- C90, PSL 3,- H40, PSL 1,- J55, PSL 3, -K55, PSL 3,- L80(1),PSL 3,-L80(13Cr), PSL 2,-L80(9Cr), FUL 1,-N80(1), PSL2,-N80(Q),PSL 3,-P110,PSL 3,-T95,PSL 3

-

-

-

-

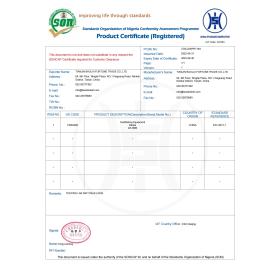

SONCAP

Issuing authority : CSIC Beijing

Valid period : 2022/8/31 - 2023/8/30

SONCAP CERTIFICATION

SONCAP certificate content includes scaffolding equipment, HS code is 73084000.Baolai can supply all of scaffolding steel pipe and accessories, include Frame Scaffolding, Walk Through Scaffolding Frame, Ringlock Scaffolding and accessories.Each type is made from several components which often include:A base jack or plate which is a load-bearing base for the scaffold.The standard, the upright component with connector joins.The ledger, a horizontal brace.The transom, a horizontal cross-section load-bearing component which holds the batten, board, or decking unit.Brace diagonal and/or cross section bracing component.Batten or board decking component used to make the working platform.Coupler, a fitting used to join components together.Scaffold tie, used to tie in the scaffold to structures.Brackets, used to extend the width of working platforms.

Our Advantage of Scaffolding:

- √Versatility

- Frame Scaffolding is frequently used in one or two tiers by residential contrators, painters, etc, but their modular frames can also be stacked several stories high for use on large-scale construction jobs.

- √Mobile & Easy to use

- Because the scaffolding rubber caster wheels with brake pads are installed at the frame bottom, the frame scaffold is easy to move, saving time and effort.

- √Convenient transportation

- Frame scaffold system has a simple structure, fewer accessories, and convenient transportation.

- √Huge market demands and High Rental returns

- Frame Scaffolding system for sale and the rental market is very huge. Because this frame scaffolding is not only can be used in outdoor construction but also be used in Indoor building.

- √Versatility

-