Search This Supplers Products:Steel Pipe ManufacturerWelded Steel Pipe ManufacturerSeamless Steel Pipe ManufacturerERW Steel Pipes Manufacturer

6 Common Uses for Cold Rolled Steel

time2023/06/13

- The processing temperature of cold-rolled steel is much lower than the recrystallization temperature of steel, so it has many advantages. Read on to learn more about cold rolled steel.

Not all metal fabrication processes involve heating steel above its recrystallization temperature. For example, cold rolling is performed at room temperature. Not surprisingly, rolling and forming steel at room temperature requires greater pressure. However, since the processing temperature of cold-rolled steel is much lower than the recrystallization temperature of the steel, it has many advantages. Below we discuss common uses for cold-rolled steel. But first, let's understand what cold-rolled steel is, how it is formed, and what are the advantages of cold-rolled steel over hot-rolled steel.

What is Cold Rolled Steel?

Cold-rolled steel is a steel that does not use hot working. Self-cooling steel goes through a physically intensive process. As opposed to hot rolling, which is used to make hot-rolled steel, cold rolling can only be done when the steel is below its recrystallization temperature.

How Is Cold Rolled Steel Formed?

Cold rolling is carried out at room temperature. Using mechanical stress rather than heat to change the structure of metals. The strength of steel can be increased by up to 20% through strain hardening, which also improves the surface quality of the metal.

Advantages of Cold Rolled Steel

During cold rolling, when metal is subjected to mechanical stress, it causes permanent changes in the crystal structure of the metal. This results in increased strength and generally improved corrosion resistance.

In addition to improved surface finish, another advantage of cold rolling is greater dimensional accuracy. This process is ideal for steel products that need to be manufactured with extremely tight tolerances.

Given the many advantages of cold-rolled steel, it is widely used in garages, steel sheds, household appliances, sanitary ware, packaging materials, aerospace components, and production machinery.

The Following Are Common Uses for Cold Rolled Steel:

Building Parts

In the construction industry, cold-rolled steel is commonly used to manufacture beams, columns, composite profiles, slabs, and other important metal components.

Also, it is used in different construction projects like granaries, railways, bridges, storage racks, sheds, gutters, roof and wall systems, buildings, garages, etc.

Production Machinery

Cold-rolled steel has been tested to increase strength by up to 20%. In addition, cold rolling has high drawing performance, excellent mechanical properties, and low yield strength. Cold-rolled steel can also be easily cut, punched, drilled, bent, and formed with good results.

Metal Furniture and Appliances

Due to its mechanical stress process, cold-rolled steel exhibits a smooth and strong surface. It can also be rolled thinner by up to 50%, making it ideal for metal furniture and appliance manufacturing. Not only does it guarantee you a longer lifespan, but it also provides a more visually appealing and aesthetically pleasing appearance.

Automobile Industry

Steel is a common component of the automotive industry. Cold-rolled steel, in particular, is more commonly used than hot-rolled steel due to its wear-resistant and shock-resistant properties.

In such industries, cold-rolled steel is used in the manufacture of load-bearing elements for vehicles and automobiles. In addition, it can be used to make car seat components, electric motors, fuel tanks, etc.

Manufacturing

In the manufacturing industry, cold-rolled steel is also a widely used steel. Below are the following common cold-rolled products:

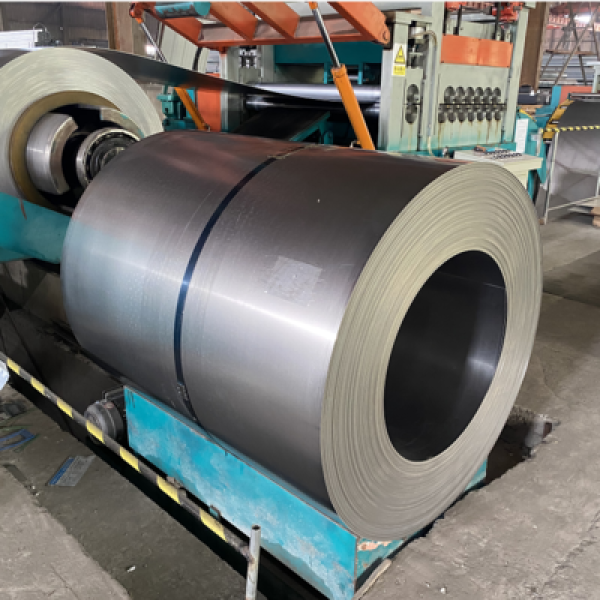

- Steel Coil – A finished, thin, flat sheet or strip of steel called a cold rolled coil.

- Steel Tubes - Steel tubes with a hollow length and section are called cold rolled steel tubes.

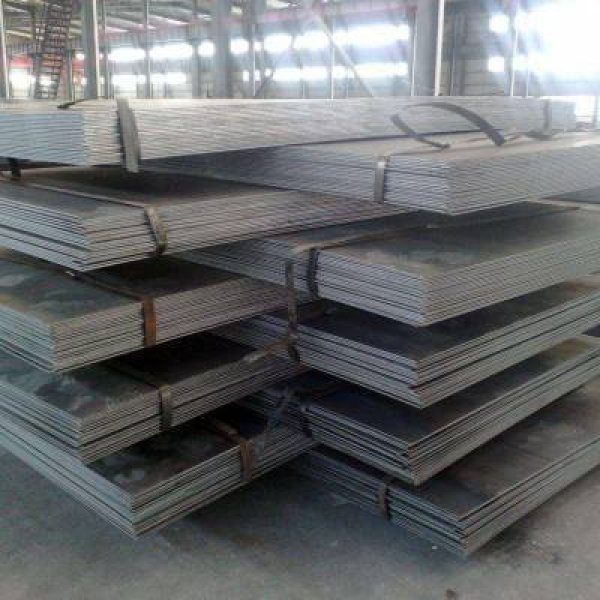

- Steel Plate – A thin, flat, rectangular sheet of metal called a cold-rolled steel plate.

- Painted Steel – Cold rolled steel has excellent paintability and formability, which is why it is the base metal for all kinds of steel, including galvanized steel.

Other Uses

Finally, the use of cold-rolled steel is not limited to the above. It can also be used in many other applications. Here is a list for your reference:

- Plumbing or lighting

- Aerospace parts

- Packaging materials

- Conveyor system

- Hardware accessories

- Exhaust pipe

- Toolboxes and other metal containers

- Precision instruments

- Tables and chairs

- Water heater

- Lawn mowers

- Railway vehicles

Key Points

When it comes to uses for cold-rolled steel, you'll find the material a staple in a variety of automotive, manufacturing, and construction applications.

If your project requires cold-rolled steel, Baolai is the right choice for you. We are a professional custom steel plate and steel pipe manufacturer in China. We are specialized in the production, trade, and import and export of steel plates, steel coils, fire pipes, ERW pipes, HDG steel pipes, seamless steel pipes, LSAW steel pipes, SSAW steel pipes, and building materials. We have more than 20,000 tons of pipe products in stock. Some specifications can be shipped today, please contact us for a quotation.

Cold rolling is a steel plate that further thins the No.1 steel plate to a target thickness at room temperature.

The main industries that consume cold-rolled steel sheets include construction, machine building, automotive.