Search This Supplers Products:Steel Pipe ManufacturerWelded Steel Pipe ManufacturerSeamless Steel Pipe ManufacturerERW Steel Pipes Manufacturer

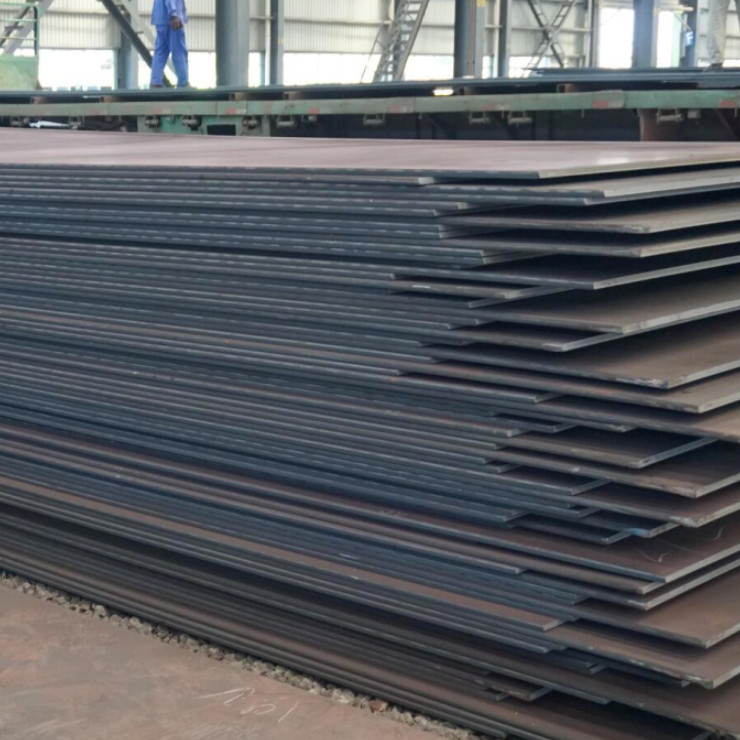

Advantages of Hot Rolled Steel Plate

time2023/05/30

- There are two different types of rolled steel plates, hot-rolled and cold-rolled. In order to help you make an informed decision, we will discuss the relevant information on hot-rolled steel plates in detail.

There are two types of rolled steel plates - hot rolled steel plates and cold rolled steel plates. Each offers unique advantages for various applications. Optimizing material selection is critical for any application. This is the reason know that hot-rolled steel is better than cold-rolled steel. This is due to their improved mechanical properties.

To help you make an informed decision, we will discuss in detail what hot-rolled steel sheets are, how they are formed and what are the advantages of hot-rolled steel sheets.

What Is Hot Rolled Steel Plate?

Many customers often ask our team what is hot rolled steel plate. But it's important to keep in mind that the term "hot rolled" does not refer to any grade or design of steel. Instead, it refers to how the steel plate is processed.

Rolling refers to the metal manufacturing process that utilizes a series of rolls to change shape, increase uniformity, and/or improve the mechanical properties of a material. Hot-rolled steel sheets are rolled at temperatures above their recrystallization temperature, typically 900℃ or 1,700℉ or higher.

Hot-rolled steel sheets show improved workability due to extremely high temperatures. Therefore, it is easier to form various shapes and sizes according to application requirements.

How Is Hot Rolled Steel Plate Formed?

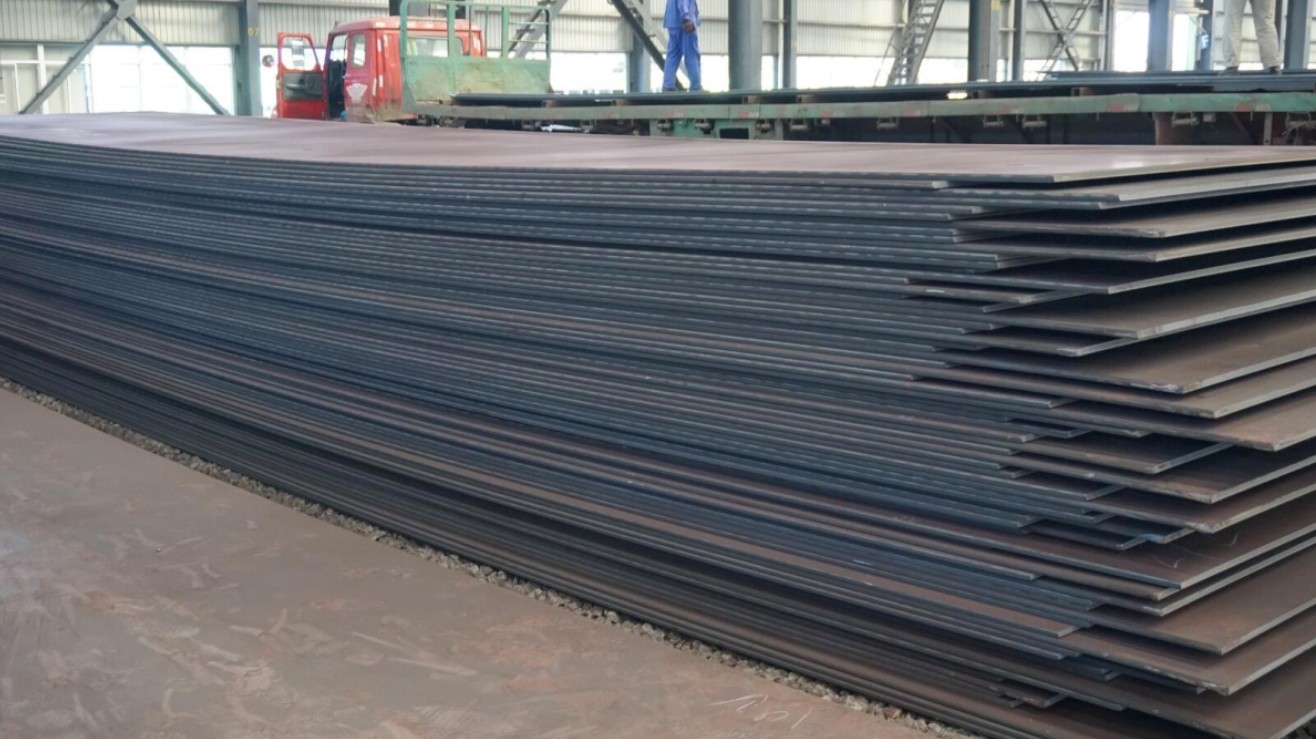

The hot rolling process starts with a large rectangular metal slab called a billet. Billets are first heated and compressed into coils. The billet is passed while hot through a set of rollers to achieve the desired dimensions. In the production of hot-rolled steel sheets, the rolled steel is repeatedly twisted into coils and cooled. Continuous rolling to form the desired shape: sheet metal or profiles with a thickness of 3 mm or more.

Between hot-rolled and cold-rolled steel sheets, the former has a better advantage because it requires less force to produce, thus reducing costs.

Hot-rolled steel sheets are easier to produce in larger quality products and therefore have lower market prices. However, it shrinks slightly as it cools. Because of this, common applications for hot-rolled steel sheets include automotive parts (frames, rims), construction materials (beams, doors, shelves), and railway components where precision is less important.

The Following Are the Advantages of Hot Rolled Steel Plates:

Cut Costs

As mentioned above, the cost of producing hot-rolled steel sheets is lower because the process requires less effort and manpower. Hot-rolled steel is easier to shape and mass produce than cold-rolled steel. Overall, it is less expensive to produce than its cold-rolled counterparts.

Small Internal Stress

The hot rolling process ends with the steel gradually cooling down on its own, thereby normalizing the material. In doing so, it releases most, if not all, of the internal pressure. As a result, the formed steel part is less likely to crack or deform once it has cooled completely.

Hot rolling changes the material properties of the steel sheet, resulting in increased durability and ductility.

Extensibility is especially important when forming various shapes for your application. That's not to say that hot-rolled steel doesn't deform - in fact, it deforms very slightly toward the end of the process, forming a slightly trapezoidal shape rather than a perfect right angle. But once the whole process is complete, there are fewer internal factors affecting the material's structure, so it's less likely to break.

Wide Range of Use

Hot-rolled steel sheets come in a variety of sizes and are easy to manipulate or cut, so they have many common uses. In particular, steel plates are used in various construction projects and industrial purposes. Hot-rolled steel is great for situations where the desired metal does not have a specific size.

The application range of hot-rolled steel plates includes bridges, automobiles, ships, high-pressure vessels or equipment, and various tools.

Key Points

We've discussed the advantages of hot-rolled steel in this article, and we hope you've learned a thing or two that will affect your decision on which material to use for your next project.

As we mentioned before, there is no automatically better choice between hot-rolled or cold-rolled; the specific usage and context should still make that decision for you.

If you are looking for where to find hot rolled steel plates or other steel products in China, then BAOLAI is your best choice! Not only do we provide high-quality steel, but we also provide excellent pre-sales and after-sales services that are sure to make you proud.

BAOLAI is a professional custom steel coil and steel plate manufacturer. As a first-class manufacturer, we are specialized in production, trade, and import and export. We provide ODM&OEM, processing, logistics management, testing, and other value-added services to make your project go smoothly. We are more than a sales force. Our technical team is dedicated to guiding project needs and providing expert guidance from start to finish. If you want to buy a plate or steel, please contact us.