Search This Supplers Products:Steel Pipe ManufacturerWelded Steel Pipe ManufacturerSeamless Steel Pipe ManufacturerERW Steel Pipes Manufacturer

7 Surprising Uses for Steel Coil in Industry

time2023/04/19

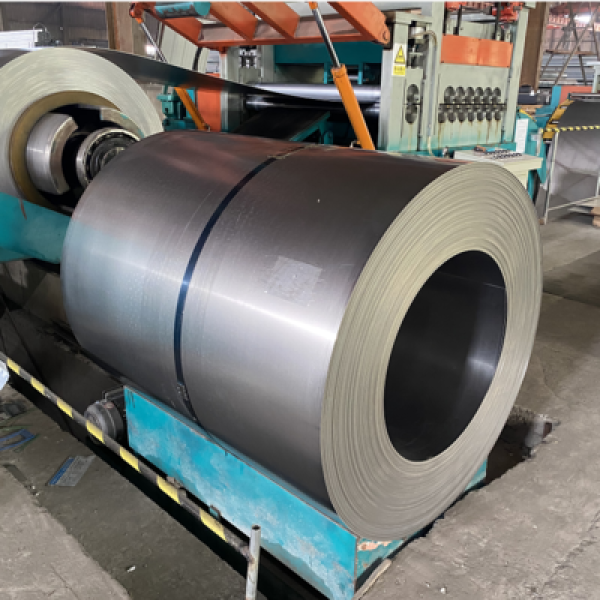

- The steel coil is an important commodity in most industries. In this article, we explore 7 uses for steel coils across various industries and why they play a key role in manufacturing and construction.

Steel is an extremely important commodity for most industries, especially engineering, and machinery. According to the world steel association, world crude steel production will reach 1,950.5 million tonnes (Mt) in 2021. There are more than 3,500 different grades of steel with many different physical, chemical, and environmental properties. Steel is processed and rolled into coils, which are then used as raw materials for different purposes. There are countless uses for steel coils. Coils of steel are used in many ways in the manufacture of modern goods, from cars to houses.

There are two main types of steel coils: hot-rolled steel coils and cold-rolled steel coils. Today, you can manage your inventory by buying Steel Coil online from trusted platforms at affordable prices. Baolai is one such online platform that allows you to buy and source steel online for your business quickly and easily.

Let's take a look at the different uses of steel coils.

The Use of Steel Coil

The type of coil required depends on its use. For example, hot-rolled steel is often used in railway tracks and construction projects, while cold-rolled steel is used to build structures such as beams, columns, and profiles.

1. Automobile Manufacturing

Steel coils are the main element in the manufacture of cars. Nearly all new vehicle designs use advanced high-strength steel (AHSS). 60% of today's automotive body structures are made of AHSS. AHSS paves the way for lighter, optimized vehicle designs that improve safety and fuel efficiency.

According to the curb weight of the whole vehicle, the steel used for the vehicle is distributed as follows:

- 40% for body structure, panels, doors, and decklids for high strength and energy absorption in the event of a crash

- 23% of the drive train, the engine block is made of cast iron, and the wear gears are made of machinable carbon steel

- 12% of the suspension is made of rolled high-strength steel strips.

- The remainder is used for wheels, tires, fuel tank, steering, and braking systems.

2. Rail Manufacturing

Steel played a key role in the development of railway tracks. The tracks were originally made of wood and then iron, but were soon replaced by steel. A hot-rolled coil of grade 1084 or higher is used to make most modern railroad tracks. This is medium carbon steel made from natural iron ore rolled track steel. This creates a steel blend that can withstand more abuse than rolled steel alone.

Rails that carry extra weight or travel at greater speeds, such as freight rail lines, will require stronger rails. Alloys such as titanium, chromium, tin, and vanadium were added to these rail lines to make them harder and stronger.

3. Making Food Industry Equipment

There are a wide variety of steel coils used in different industries. The food industry relies on stainless steel coil manufacturing machinery. It is also used in the manufacture of ice makers, blenders, hot and cold holders, cooking utensils, and more. The food industry prefers to use stainless steel for equipment as it does not react with food and is strong enough to last a lifetime.

Austenitic-grade stainless steel is used in the manufacture of cutlery, hollowware, kitchen utensils, brewing vessels, and milk jugs. Highly alloyed austenitic grades for storage and transport of corrosive food and beverage products. Molybdenum-containing stainless steel grades are resistant to salty foods.

4. Building and Bridge Construction

Steel coils are used in a wide variety of applications in the construction industry. It is used to build buildings and bridges. The construction industry accounts for more than 50% of the world's steel demand. The use of steel coils in building construction includes the manufacture of products such as structural profiles, steel bars, and steel coil products. Structural profiles provide the rigid framework of buildings and account for 25% of the steel used in buildings. Panel products are made into insulating panels for roofs, purlins, interior walls, ceilings, cladding, and exterior walls.

Steel bridges are widely used in different structural forms such as road bridges, railway bridges, and pedestrian bridges all over the world. The construction industry prefers steel coil over other building materials because of its strength, ductility, ease of fabrication, and rapid construction capabilities. It has a relatively good strength-to-cost ratio and stiffness-to-weight ratio, making it a better construction material for quality and profitability.

5. Assembly Line

Over the past 50 years, steel pipe has become a popular choice for oil and gas transmission. Steel coils are used to make pipe typically for pipes operating at 100 psig or higher. Steel coils are used to make high-pressure pipes because steel allows for thinner-walled pipes. This significantly reduces plumbing costs as well as construction costs. Welding time and material shipping/handling costs are also reduced.

6. Defensive Equipment

All militaries use military-grade steel in one form or another. It can be used not only as a protective material, but also in the manufacture of combat products such as submarines, aircraft, tanks, armor, and artillery. Not only is it high quality, but it's often the more economical option. The two most important factors regarding military steel are strength and ballistic limit.

7. Aviation

Stainless steel coils are widely used in the manufacture of aircraft. The material can withstand heavy loads and allows for cleaning and organization. This helps aerospace companies save time and money during the manufacturing process. These coils also allow for precision manufacturing, which is critical to the aerospace industry.

Engine and exhaust components, landing gear components, and critical superstructure joints are where steel is used on aircraft. The high tensile strength of stainless steel helps the aircraft absorb impact stress. Stainless steel coils increase durability and reduce the risk of failure during flight.

Industrial Steel: The Way Forward

Different grades of steel are used in different industries. Therefore, if steel is an important raw material in your production process, it is crucial to source the correct grade of steel of the highest quality. Steel coils can now be easily sourced online with the added benefits of price comparison, faster delivery, and quality.

Baolai is a professional custom steel plate and coil manufacturer. As a first-class manufacturer, we are specialized in production, trade, and import and export. The after-sales service and support provided by Baolai simplify your work and truly achieves one-stop service. We provide value-added services such as ODM & OEM, processing, logistics management, and testing to keep your projects running smoothly. We are more than just a sales force. Our technical team is dedicated to guiding project needs and providing expert guidance from start to finish. If you want to buy steel plates or steel products, please contact us.

Hot-rolled coils (HRC) are a type of sheet product resembling a wound steel strip and are produced at hot-rolling mills.

Cold rolling is a steel plate that further thins the No.1 steel plate to a target thickness at room temperature.

Hot-dipped galvanized steel coil is made from steel plate, and the surface is coated with a layer of zinc.