Search This Supplers Products:Steel Pipe ManufacturerWelded Steel Pipe ManufacturerSeamless Steel Pipe ManufacturerERW Steel Pipes Manufacturer

Welded Steel Pipe Standards and Classification

time2023/01/10

- Welded steel pipe is a steel pipe that is welded after steel or steel strip is crimped and formed by a machine unit and a mold. Read on to learn more about welded steel pipe.

Welded steel pipes are referred to as welded pipes for short, and are commonly used steel pipes or steel strips that are welded after being crimped and formed by a unit and a mold. Welded steel pipe has a simple production process, high production efficiency, many varieties and specifications, and less equipment investment, but its general strength is lower than that of seamless steel pipe.

Since the 1930s, with the rapid development of continuous rolling production of high-quality strip steel and the advancement of welding and inspection technology, the quality of welds has been continuously improved, and the varieties and specifications of welded steel pipes have increased day by day, and have been used in more and more fields, especially in Heat exchange spare tubes, decorative tubes, medium and low-pressure fluid tubes, etc. have replaced seamless steel tubes.

The production process of straight seam welded pipe is simple, the production efficiency is high, the cost is low, and the development is rapid. The strength of the spiral welded pipe is generally higher than that of the straight seam welded pipe, and the welded pipe with a larger diameter can be produced with a narrower billet, and welded pipes with different diameters can be produced with the same width billet. But compared with the straight seam pipe of the same length, the weld length is increased by 30~100%, and the production speed is lower.

Generally speaking, the diameter of the pipe can be divided into outer diameter, inner diameter, and nominal diameter. The outer diameter of the pipe whose material is a spiral steel pipe is represented by the letter D, followed by the size and wall thickness of the outer diameter, such as a seamless steel pipe with an outer diameter of 108.

National Standard for Welded Steel Pipe

1. GB/T3091-1993 (galvanized welded steel pipe for low-pressure fluid transportation). Mainly used for conveying water, gas, air, oil, and heating hot water or steam and other general lower-pressure fluids and other purposes. Its representative material is Q235A grade steel.

2. GB/T3092-1993 (galvanized welded steel pipe for low-pressure fluid transportation). Mainly used for conveying water, gas, air, oil, and heating hot water or steam and other general lower-pressure fluids and other purposes. Its representative material is Q235A grade steel.

3. GB/T14291-1992 (welded steel pipes for my fluid transportation). It is mainly used for straight seam welded steel pipes for my compressed air, drainage, and shaft discharge gas. Its representative material is Q235A and B-grade steel. GB/T14980-1994 (large-diameter electric-welded steel pipes for low-pressure fluid transportation). Mainly used for conveying water, sewage, gas, air, heating steam, and other low-pressure fluids and other purposes. Its representative material is Q235A grade steel.

4. GB/T12770-1991 (stainless steel welded steel pipe for mechanical structure). Mainly used in machinery, automobiles, bicycles, furniture, hotel and restaurant decoration, and other mechanical parts and structural parts. Its representative materials are 0Cr13, 1Cr17, 00Cr19Ni11, 1Cr18Ni9, 0Cr18Ni11Nb, etc.

Welded Steel Pipe Classification

A. Welded pipes can be basically divided into two types: straight seam welded pipes and spiral welded pipes according to the shape of the weld seam:

1. Straight seam welded steel pipe: the production process is simple, the production efficiency is high, the cost is low, and the development is rapid. There are many straight-seam welded pipes for general industrial use.

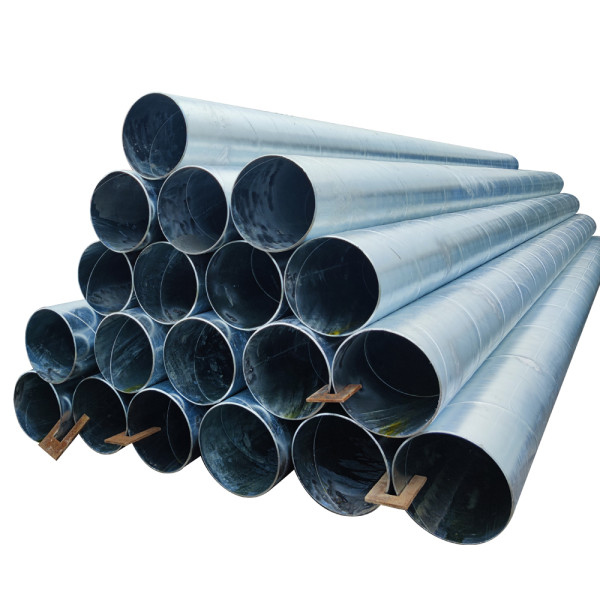

2. Spiral welded steel pipe: the strength is generally higher than that of the straight seam welded pipe, and the welded pipe with a larger diameter can be produced with a narrower billet, and welded pipes with different diameters can also be produced with same width billet; Compared with that, the weld length of spiral welded steel pipe is increased by 30~100%, and the production speed is lower; therefore, most of the welded pipes with smaller diameters adopt straight seam welding, and most of the large diameter welded pipes adopt spiral welding.

B. Welded pipes are divided into the following types according to their uses:

1. General welded steel pipe: general welded steel pipe is used to transport low-pressure fluid. It is made of Q195A, Q215A, and Q235A steel.

It can also be made of other soft steel that is easy to weld. The steel pipe should be subjected to water pressure, bending, flattening, and other experiments. The quality has certain requirements, usually, the delivery length is 4-10m, and it is often required to be delivered to a fixed length (or multiples). The specification of the welded pipe is expressed by the nominal diameter (millimeter or inch). There are two kinds of ordinary steel pipes and thickened steel pipes, and the steel pipes are divided into two types: threaded and non-threaded according to the shape of the pipe end.

2. Galvanized welded steel pipe: In order to improve the corrosion resistance of the steel pipe, the general steel pipe (black pipe) is galvanized. The galvanized steel pipe is divided into hot-dip galvanized steel and electric steel zinc.

3. Oxygen-blowing welded steel pipe: used for steel-making oxygen-blowing pipe, generally small-diameter welded steel pipe, the specification is made of eight kinds of 08, 10, 15, 20 or Q195-Q235 steel strips from 3/8 inch to 2 inches. In order to prevent corrosion, some are aluminized.

4. Wire casing: It is also an ordinary carbon steel electric welded steel pipe, which is used in concrete and various structural power distribution projects. The commonly used nominal diameter is from 13-76mm.

5. Metric welded steel pipe: the specification is in the form of seamless pipe, and the welded steel pipe expressed by outer diameter * wall thickness in millimeters is welded with ordinary carbon steel, high-quality carbon steel, or ordinary low-alloy steel with hot and cold strips, or with After hot-tropical welding, it is made by cold drawing. Metric welded pipes are divided into general energy and thin-walled. They are generally used as structural parts, such as drive shafts, or conveying fluids. Thin-walled pipes are used to produce furniture, lamps, etc. The strength and bending of the steel pipe must be ensured.

6. Roller tube: used for belt conveyor roller electric welded steel pipe, generally made of Q215, Q235A, B steel, and 20 steel, with a diameter of 63.5-219.0mm. For the bending degree of the tube, the end face should be perpendicular to the center line, and the ellipticity There are certain requirements, and the water pressure and flattening tests are generally carried out.

7. Transformer tube: used to manufacture transformer cooling tubes and other heat exchangers. It is made of ordinary carbon steel and requires flattening, flaring, bending, and hydraulic tests. Steel tubes are delivered in fixed lengths or doubled lengths. There are certain requirements.

8. Special-shaped pipes: square pipes, rectangular pipes, hat-shaped pipes, steel pipes for hollow plastic steel doors and windows, welded by ordinary carbon-bonded structural steel and 16Mn steel strips, mainly used as agricultural machinery components, steel windows, and doors, etc.

9. Welded thin-walled steel pipes: mainly used to make furniture, toys, lamps, etc. In recent years, thin-walled tubes made of stainless steel strips have been widely used in high-end furniture, decoration, fences, etc.

10. Spiral welded steel pipe: It is made by rolling low-carbon carbon structural steel or low-alloy structural steel strip into a tube blank according to a certain helical angle (called forming angle), and then welding the pipe seam. It can be used with Narrower strips to produce larger-diameter steel pipes. Spiral welded steel pipes are mainly used for oil and natural gas transmission pipelines, and their specifications are expressed by outer diameter * wall thickness.

C. According to the shape of the end, it is divided into round welded steel pipes and special-shaped (square, flat, etc.) welded steel pipes.

The above briefly introduces the classification and standards of welded steel pipes. If you want to buy welded steel pipes, please contact us.

Baolai is a professional custom seamless and welded pipe manufacturer. As a first-class manufacturer, we are specialized in production, trade, and import and export. Our seamless steel tubes are available in sizes 1/2"-36" to API, ASTM, BS, DIN, and JIS standards for the transportation and construction of liquids and gases.

Pre-galvanised steel pipes are made from galvanised steel strip to prevent rust and corrosion.

IMC is precision manufactured for economical protection and long lasting value for the electrical raceway system.

SSAW steel pipe is a type of spirally welded steel pipe produced by using the double-sided submerged arc welding method.

ASTM A500 rectangular tube is welded from strip steel or plate after crimping, it is used in steel structure, construction, etc