Search This Supplers Products:Steel Pipe ManufacturerWelded Steel Pipe ManufacturerSeamless Steel Pipe ManufacturerERW Steel Pipes Manufacturer

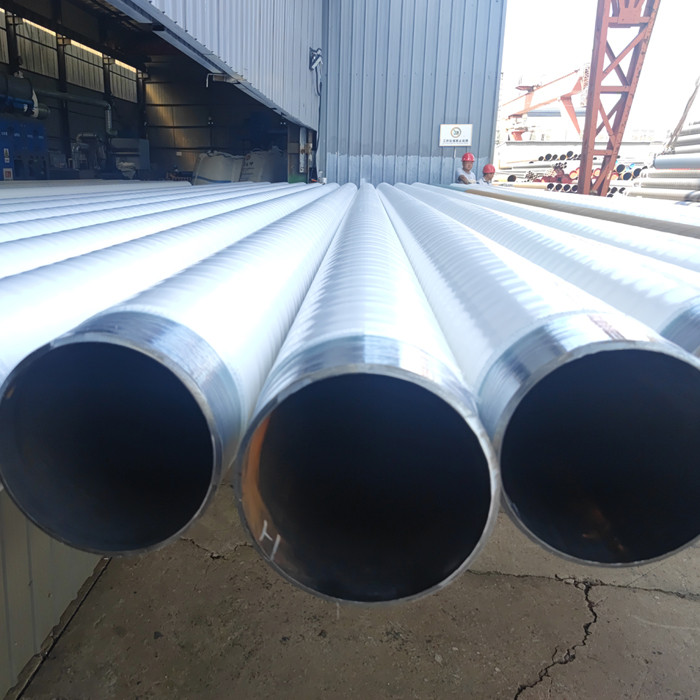

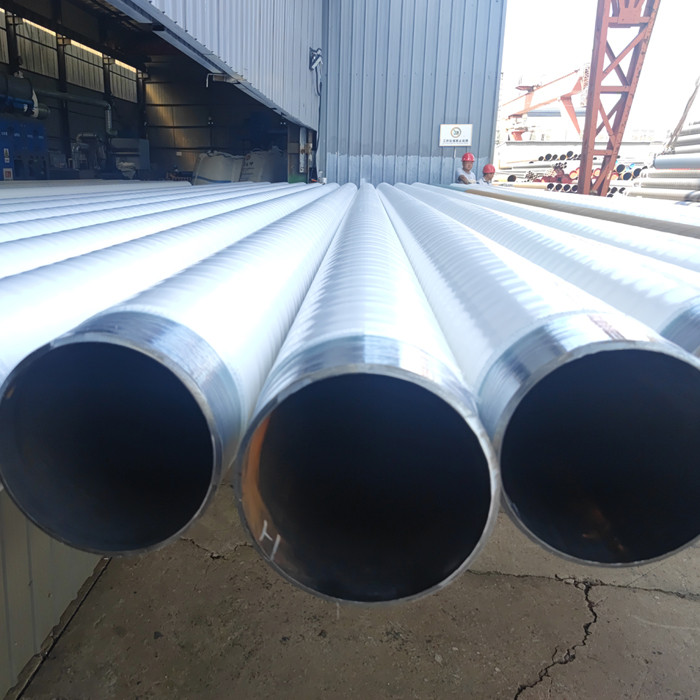

ERW 3LPP oil pipelines are Producing in Baolai Group

sourceCompany Products

publisherBaolai Fortune

time2022/09/14

- 3LPP Coated Pipes consists of multilayer anti-corrosion coatings consisting of an inner layer of fusion bonded epoxy layer, the middle layer is an adhesive layer and an outer layer of polypropylene.

3LPP Pipe Coating

3 Layer Polypropylene Coating Pipeline supplier in China

What's the 3LPP Coating?

3LPP means 3-Layer Polypropylene, which is a multilayer coating composed of three functional components.

While the inner 3LPP Coating is what prevents chemical damage or decay, it is the outer coat that provides the material with good toughness making it the most tougest and durable coating solutions possible.

3LPP systems provide excellent pipeline protection for small and large diameter pipelines at low up to high operating temperatures.

3LPP Coating Steel Pipe Process

3LPP Coating Process

First, the steel pipe is heated while sandblasting to remove rust. This step can make the epoxy layer better adsorb on the surface of the steel pipe and make it firmer.

Secondly, glue the sandblasted steel pipes to connect them together for easy operation.

The third step is to spray three coats of paint. The initial layer of a 3 Layer Polypropylene Coating includes the application of a high-performance Fusion Bonded Epoxy primer or in short an FBE primer via fusion bonding. The next step is the application of a copolymer, which acts as an adhesive. The final step of this process consists of an outer coat of polypropylene.

Fourth, after water cooling, the coating on the pipe ends is removed to facilitate connection of pipes.

Finally, marking on the steel pipe as your request and packing with plastic.

3LPP Coated Pipe Specifiaction

3LPP Coating is a multi-layer coating according to DIN 30670, ISO 21809-1, CAN/CSA Z245.21 standards

|

3LPP

|

3 Layer Polypropylene Coating

|

||

|

Min -Max Pipe Diameter

|

3.5" - 48"+ ( 90 - 1220mm+ )

|

||

|

Temperature Range

|

-20-110℃

|

||

|

Bendability

|

Yes

|

||

Layers under 3LPP coating | 1st Layer : Fusion Bonded Epoxy (FBE) 2nd Layer: copolymer adhesive 3rt Top Layer: polypropylene | ||

Export Market | Indonesia, Malaysia, UAE, South Africa, Egypt, Congo, USA, India |

3LPP Coated Pipe Advantage

1. Its a multilayer coating and most durable

2. 3LPP Pipeline Coating are suitable for high operating temperatures

3. 3LPP coating can be customized as per project requirement

4. It can be applied on various thickness pipes

5. It has excellent mechanical protection

6. Can be applied on Large or Small Diameter Pipelines

7. Cathodic disbondment Resistance

8. The 3LPP coated pipes Known for high performance and an extended life.

What's the difference of 3LPE and 3LPP Coating?

The same as 3LPE, the buried steel pipe with 3LPP coating is used for the transportation of water, oil, gas and other media. Unlike 3LPE, its third layer is polypropylene. And it has more advantages than 3LPE in the following aspects, and of course the price will be higher:

1. High applicable temperature: the working temperature of the coating can reach 110℃~150℃.

2. Long service life of 3PP at high temperature: DIN30678 says that the life is 30 years at 80°C, 15 years at 90°C, and 8 years at 100°C. (3PE when the temperature is higher than 80℃, the PE layer will soften)

3. Good peel strength and indentation hardness at high temperature

4. The impact resistance is suitable for a wide range of temperatures

Sandblasting

3LPE

3LPP

Packaging