What differences between 3PE (3LPE Coated Pipe) and FBE Epoxy Coating Pipe?

time2023/02/01

- BAOLAI can supply 3LPE coated pipes or FBE coated pipes in different standards and types, so please do not hesitate to contact us for a quotation if you have such a requirement.

Differences between 3PE and FBE

When people buy steel pipes for use in piping systems, they always see the pipes being required to be epoxy coated, such as 3PE (3LPE) or FBE.

So what exactly are epoxy coated (3LPE/3PE or FBE) pipes? In which situations are they used?

FBE pipes are coated with an epoxy resin coating and can be used for internal and external coating, but mostly for internal coating of pipes. The designation is fusion bonded epoxy resin pipe.

3LPE pipes are coated internally with epoxy resin with an adhesive layer in the middle and externally with a polyethylene layer. 3LPE is only used for the external coating of pipes.

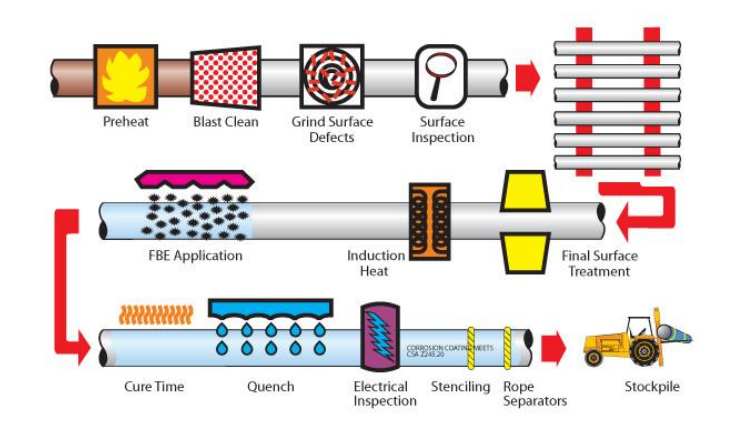

FBE Production process

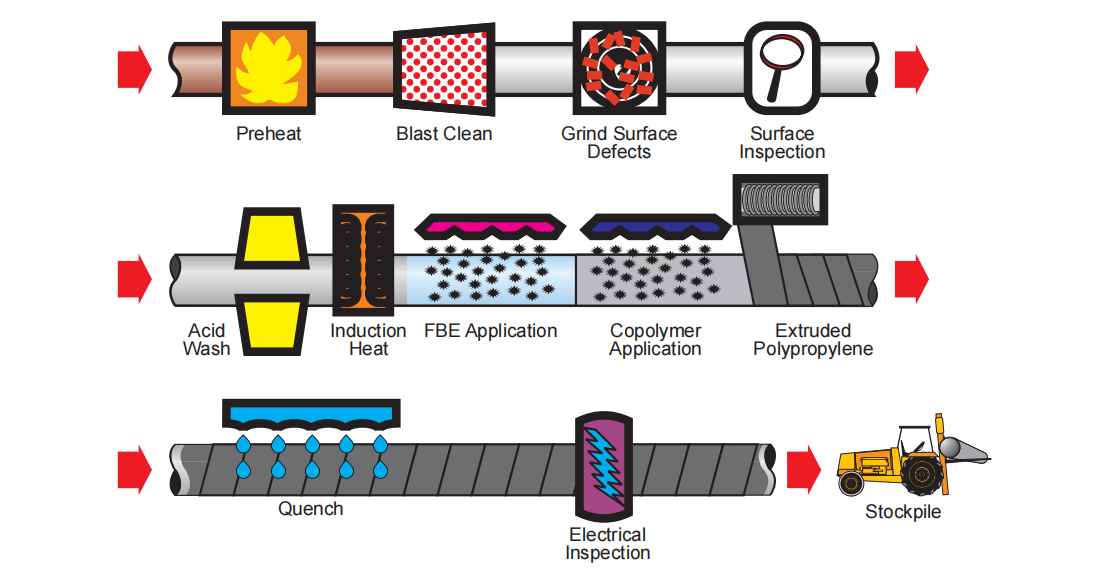

3LPP Production process

Applications

3PE/3LPE coated pipes and FBE epoxy resin coated pipes are widely used in pipeline systems for the transport of oil, gas, water and other liquids. They are highly resistant to corrosion from chemicals, moisture, harmful environments, etc.

What types of pipes can be coated with 3LPE/3PE or FBE?

Almost all types of steel pipes can be coated with FBE or 3LPE.

Most steel pipes used for fire protection are coated, for example

ASTM A53 pipe (hot dipped galvanised steel pipe)

Of course, carbon steel pipes, stainless steel pipes and alloy steel pipes are also available.

What is FBE (Fused Bonded Epoxy) coated steel pipe?

FBE coated steel pipe refers to fusion bonded epoxy resin coated steel pipe. It can be applied as an external or internal coating, using hot resin for the pipe. A dry powder with a thickness of 400-600 microns is applied to the heated surface of the pipe. Once the FBE is applied to the surface of the pipe, the FBE film provides a very hard surface with a strong adhesion to the pipe surface. the FBE layer is uniform in shape and has good resistance to chemical reactions.

Features of FBE epoxy coated pipes

FBE coatings can be made as single and double layers.

FBE double coated pipes are recommended for offshore pipelines and pipeline systems operating in harsh environments where it offers high performance in terms of impact resistance and flexibility. Providing suitable protection for the coating from damage during transport and construction.

And FBE single layer coated pipe is the general type of FBE coated pipe. It provides a rough, non-slip surface for pipes that require a concrete coating. A special fusion-bonded epoxy powder is mixed with solid epoxy resin and other adhesive materials to help adhere to the pipe surface.

The advantages of FBE coated pipes are ease of spraying, no pollution and good resistance to high temperatures (-40°C to 85°C).

High strength and good resistance to bending.

Strong adhesion, good integrity and resistance to soil stress and abrasion.

FBE coated steel pipes are usually buried in soil and under water at temperatures between -40 and 85°C.

On the other hand, the drawback of FBE pipe is that it does not have good resistance to mechanical properties and wet conditions.

What is 3LPE coated pipe?

3LPE coated pipe consists of 3 layers of coating, the first layer is an FBE coating, the middle is an adhesive layer and the outside is a polyethylene layer. 3PE coated pipe is another new product developed since the 1980s based on FBE coating, which contains an adhesive and PE (polyethylene) layer. 3PE can strengthen the mechanical properties of the pipe, high electrical resistance, water resistance, wear resistance and ageing resistance.

It protects the pipeline from heat loss, which is only 1/4 of the pipeline.

Features of 3PE/3LPE coated pipes

The service life of 3LPE coated pipes can be extended to more than 50 years under normal working temperature and pressure conditions.

Resistant to natural gas, LPG, artificial gas and other chemicals without the need for secondary anti-corrosion equipment.

3PE/3LPE is a soft and flexible material which can be extended up to 5 times its length and then disconnected.

Experiments have shown that PE pipe is four times more wear resistant than tubing, especially in areas where slurries are transported.

PE material is non-toxic and non-hazardous, a green material, and can itself be recycled without causing pollution to the environment.

Excellent electrical resistance and anti-static properties. These properties make PE pipelines suitable for use in flammable and explosive environments.

3LPE/3PE coated steel pipe mainly adopts hot melt and fusion welding methods to keep the interface and pipe connected as one. There is no water leakage or air leakage.

The weight of 3LPE layer only accounts for 1/8 of the steel pipe, which is easy to move and bend, and the welding process is convenient and quick, which reduces the cost of the whole project and has obvious economic benefits.

BAOLAI can supply 3LPE coated pipes or FBE coated pipes in different standards and types, so please do not hesitate to contact us for a quotation if you have such a requirement.