Search This Supplers Products:Steel Pipe ManufacturerWelded Steel Pipe ManufacturerSeamless Steel Pipe ManufacturerERW Steel Pipes Manufacturer

How Fire Pumps Work in Fire Protection Systems?

time2022/08/08

- Fire pumps play a vital role as first responders to fire situations, saving countless lives and property from damage.

Fire pumps play a vital role as first responders to fire situations, saving countless lives and property from damage. They are commonly found in manufacturing and industrial facilities, residential complexes, power plants, schools, hospitals, airports, commercial buildings, and offshore oil platforms. Therefore, the fire protection system is the most important of the various industry services, as its goal is to protect human life and property in strict accordance with this order.

What does a fire protection system consist of?

It has three parts: a large amount of stored water, which can be underground or on top of a building, called a fire storage tank, a dedicated pumping system, a dedicated pumping system, and a large network of pipes ending at hydrants or sprinklers (Almost all buildings require both systems).

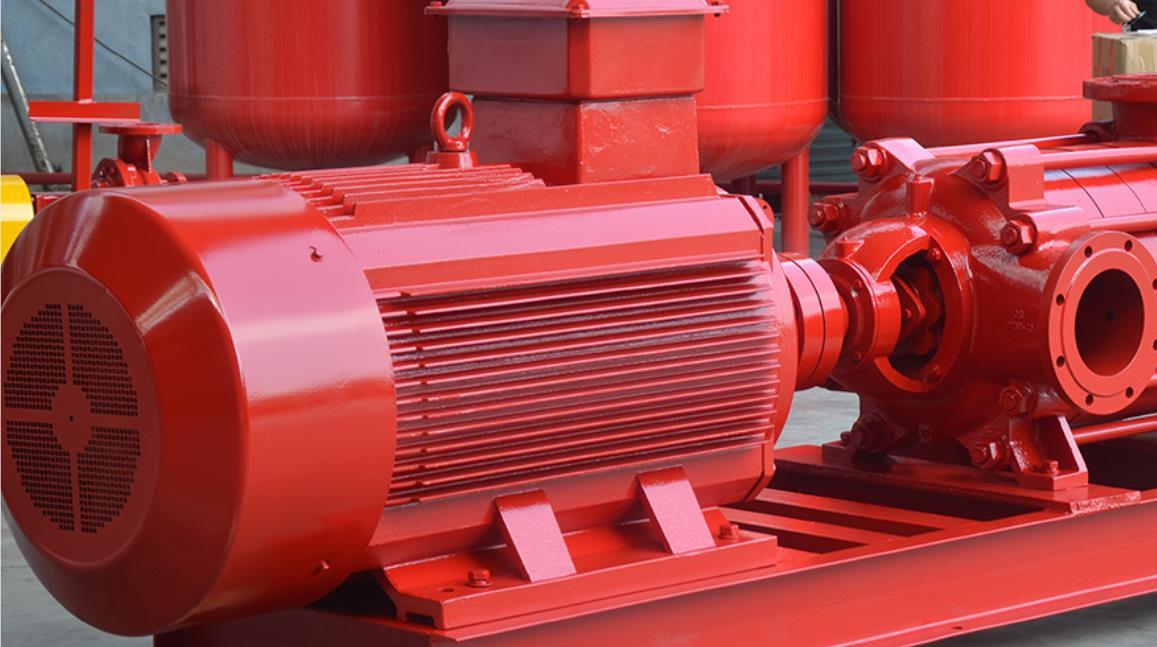

Fire pump

Fire pumps are usually housed in pump rooms very close to fire tanks. The point is that the pump should be at a level below the bottom of the fire tank so that all the water in the tank can flow into the pump by gravity.

As with all critical systems, a backup pump must have a backup pump if the primary pump fails. It is common to have a primary and backup pump that is electric, and a backup pump that is diesel driven in case of power failure. Each pump individually pumps out the required amount of water - their capacity is the same.

There is also a fourth type of pump, called the jockey pump. This is a small pump attached to the system that is constantly on to maintain the correct pressure in the electrical distribution system, usually 7kg/cm2 or 100psi. If there is a small leak in the system, the regulator pump will start to compensate. Each jockey pump will also have a backup.

These pumps are controlled by pressure sensors. When firefighters turn on hydrants or sprinklers are turned on, water drains out of the system, and pressure drops. The pressure sensor will detect this drop and turn on the fire pump. But the only way to turn off the fire pump is for firefighters to do it manually in the pump room. This is an international code of practice to avoid pump shutdown due to any failure of the control system.

Pump capacity is determined by considering many factors, some of which are:

Areas covered by hydrants/risers and sprinklers

Number of hydrants and sprinklers

Certification of area sprinklers

The type and layout of the project

They can be depicted in different ways, composed in a different way, in different scopes, covered with different interfaces, and wrapped in specially composed interfaces to protect the pipes.

The pressure sensor of the water pump will detect the pressure and after the hydrant held by the firefighter has entered several hydrant positions after the pump will start the freezing system, the pump will start the pipes, which will cause them to reach. Useless in fire, you need to do this.

Manual distribution system

These systems have an inlet for the fire truck to pump into the system. Once the fire truck will turn on the distribution system, firefighters can put out the fire in the correct location and start directing water to the fire. The inlets that allow water from the fire truck to enter the distribution system are called conjoined connections.

In it, each stair must have a wet pipe, a facing fire pipe, and fire hydrants on each floor because, in prevailing conditions, there is a path for water to flow.

In more complex and hazardous installations, water spray systems and foam systems (for hazardous materials) are used. The foam is like an insulating blanket that ignites the liquid, allowing it to flow at equal heights. The server machine whose contents are corrupted uses an entry suppression system.

It is the legal responsibility of the building owner and/or employer to ensure that suitable fire protection and firefighting equipment is in place and functioning. Annual inspections are required by a third party that meets relevant fire management qualifications and guidelines. Between annual inspections, it is recommended to run the pump for a short period of time per week to check performance. Periodic visual inspections are also recommended so that early signs of wear can be detected.

The above describes how the fire pump works, if you want to buy a fire pump, please contact us.

Baolai is a professional custom fire protection systems manufacturer. As a top manufacturer, we specialize in the production, trade, import and export of fire pipes, fire pumps, ERW pipes, hot dip galvanized steel pipes, seamless steel pipes, straight seam welded pipes, SSAW steel pipes and building materials. Baolai currently employs about 1,300 people, with 13 production lines, multiple processing lines and 4 technologically advanced laboratories. Our annual production capacity is about 5 million tons, and we export 150,000 tons per year to South and North America, Europe, Middle East, Africa, Australia and Southeast Asia.